Project G922 - Custom Steel Lighting Poles for EU Municipal Infrastructure

- SHAMANA Technical Team

- Jan 6

- 3 min read

Updated: 6 days ago

Custom Steel Lighting Poles for EU Municipal Infrastructure - Project Overview

Project Code: G922Product: Custom-designed steel lighting polesApplication: Urban public lighting infrastructureScope: Engineering validation, dimensional control, production supervision, electrical safety verification, and pre-shipment inspectionMarket: EU public / municipal projects

Project G922 involved the manufacturing and on-site validation of custom steel lighting poles intended for long-term urban deployment. The project required strict alignment between approved engineering drawings, real production output, and installation realities in public infrastructure environments.

SHAMANA was engaged to provide on-site engineering control, ensuring that what was designed was exactly what was manufactured, tested, and shipped.

Technical Specifications

(Validated Physically on Site)

All critical dimensions were measured directly on the production floor and cross-checked against approved technical drawings.

Total pole height: approx. 8,036 mm

Base flange: 400 × 400 mm

Flange thickness: approx. 16 mm

Pole structure: Tapered steel body

Service access: Integrated access door for wiring and maintenance

Surface treatment: Industrial outdoor coating, uniform and defect-free

Dimensional verification was not theoretical. Measurements were taken directly on the steel components prior to packaging.

Quality Control & Inspection Process

SHAMANA conducted a full structural and dimensional inspection, including:

Base flange dimensions and bolt-hole positioning

Verticality and straightness of the pole body

Thickness verification of load-bearing elements

Service door positioning and internal clearance

Weld quality inspection (base plate, arm joints, structural seams)

Packaging method and container loading verification

All inspections were documented photographically and validated directly on site, not via supplier self-declaration.

Inspection report project G922 - proof

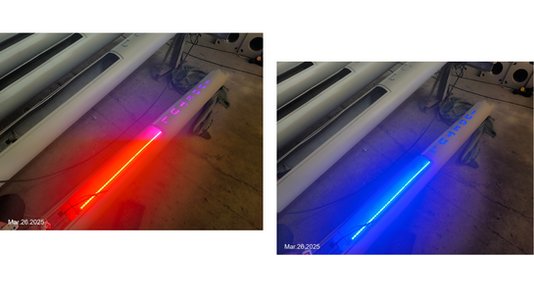

Functional test

Engineering Corrections Applied Before Mass Production

Issue Identified

During inspection, SHAMANA identified a critical structural deviation:

The curved arm terminal length was insufficient for safe welding and long-term mechanical reliability.

While visually acceptable, the shortened end reduced weld penetration area and compromised stress distribution under load.

This was a structural risk, not a cosmetic issue.

Corrective Action

Engineering correction of +30 mm minimum added to the curved arm terminal.

Updated technical drawing issued and validated before series production.

This modification significantly improved:

weld integrity

load behavior under wind and vibration

long-term fatigue resistance

The correction prevented a hidden failure risk that would not have been visible after installation.

Electrical Safety & Compliance Verification

Beyond mechanical validation, the project included electrical safety testing aligned with EU requirements.

HI-POT (Dielectric Withstand) Testing

Individual high-voltage insulation testing performed on the electrical system.

Test conditions aligned with LVD (2014/35/EU) safety requirements.

Verification of insulation integrity between live parts, secondary circuits, and accessible metal structures.

This confirms that electrical safety was physically tested, not assumed.

CE / EMC / LVD Documentation

The project is supported by:

CE EMC Test Reports

Verification of Compliance

EU Declaration of Conformity

Component-level certifications (including driver documentation)

Documentation and on-site testing are consistent and mutually reinforcing: what is declared is what was tested.

Manufacturing & Finish Assessment

Welds: Clean, continuous, no visible porosity or thermal deformation

Surface coating: Uniform, no bubbling, peeling, or contamination

Cut-outs & openings: Clean edges, controlled tolerances

Overall execution: Suitable for municipal-grade infrastructure with long service life expectations

Packaging & Logistics Control

Poles individually protected against abrasion and impact

Packaging designed to maintain straightness during transport

Container loading optimized for stability and space efficiency

No deformation or surface damage observed during packing

SHAMANA Verdict

✔️ Product execution: Good✔️ Manufacturing quality: Consistent✔️ Engineering control: Critical and effective✔️ Risk mitigation: Successfully applied before mass production

Project G922 demonstrates how on-site engineering verification prevents structural and safety risks that are commonly missed in document-only or remote sourcing models.

Implementation proof

What This Case Proves

Real sourcing is not about drawings. It is about what gets welded, measured, tested, and shipped.

Small dimensional deviations can generate major downstream risks in public infrastructure.

Engineering presence on the ground changes outcomes, not just reports.

This project demonstrates how custom steel lighting poles for EU municipal infrastructure require on-site engineering validation, dimensional control, and electrical safety testing to eliminate structural and compliance risks before mass production.