Supply Chain Engineering

Integrated China Sourcing & Vendor Risk Reduction

What we actually do

-

At SHAMANA, we don’t treat projects as isolated products or one-off orders.

-

We treat them as supply chains.

-

Supply Chain Engineering is our approach to designing, restructuring and stabilizing the entire flow behind a product — from components and manufacturing to assembly, validation and long-term continuity.

-

This is not procurement.

-

This is not sourcing as a transaction.

-

This is engineering applied to supply chains.

Supply Chain Engineering is a disciplined approach to sourcing and vendor coordination that ensures scalable, repeatable, and low-risk hardware deliveries. It combines system architecture, multi-supplier integration, and process control to support industrial and institutional deployments.

SUPPLY

What Supply Chain Engineering Solves

It is required when projects demand stable multi-supplier networks, repeatable deliveries, reduced single-source dependency, and predictable outcomes in industrial or institutional applications.

Our clients typically reach this point when they face situations such as:

-

Dependency on a single supplier or geography

-

Vendor lock-in that limits flexibility and cost control

-

Products already in production that require a supplier transition

-

Hardware systems that need parameter adjustments, not redesign

-

Growth phases where stability matters more than speed

-

Institutional or industrial projects where failure is not an option

Supply Chain Engineering is about reducing risk while increasing control.

CHAIN

How It Works – Process & Capabilities

Supply Chain Engineering is the design and execution of integrated procurement, supplier coordination, risk mitigation, and controlled hardware delivery to ensure continuity, quality, and repeatability.

In real projects, this approach includes:

-

Re-architecting supplier ecosystems to eliminate single-source dependency

-

Adjusting technical parameters to maintain performance and compatibility

-

Taking over existing production without disrupting operations

-

Opening molds, validating components and managing controlled transitions

-

Designing assembly logic, documentation and quality consistency

-

Ensuring scalability, repeatability and long-term availability

The goal is not to reinvent products, but to make them sustainable in real conditions.

ENGINEERING

A transversal capability, not a standalone service

Supply Chain Engineering is not sold as a separate operational service.

It is a transversal capability that connects everything we do at SHAMANA.

It sits above:

-

hardware integration

-

component sourcing

-

production supervision

-

quality control

-

delivery coordination

This is the layer that ensures all these elements work together as a coherent system.

Industrial & Institutional Applications

Supply Chain Engineering is applied across public service installations, energy infrastructure deployments, utility hardware rollouts, and commercial system integrations.

-

Our Supply Chain Engineering methodology is applied across different industries and project types, including:

-

Public and institutional projects

-

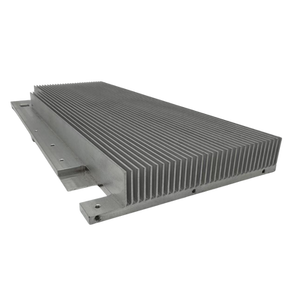

Industrial components and assemblies

-

Utilities and infrastructure

-

Hardware systems and devices

-

Hospitality and commercial environments

-

Different outcomes, same underlying discipline.

Proof & Case Evidence

Our case studies reflect this approach in practice:

-

Project G308 – DOCUBOX

Iterative hardware development and deployment for public authorities -

Project G922 - Custom Steel Lighting Poles for EU Municipal Infrastructure

-

Hexapolar Diagnostic Cable Assembly for Utility Applications (PR034)

Production takeover, tooling development and stable annual volumes for utility networks

Transition from single-source dependency to a flexible, multi-supplier model

-

These are not concepts. They are executed supply chains.

Real Cases of Supply Chain Engineering

Why this matters

In today’s environment, companies don’t fail because they lack ideas.

They fail because their supply chains are fragile.

Supply Chain Engineering provides:

-

predictability

-

resilience

-

cost transparency

-

operational continuity

It allows products and systems to evolve without breaking the flow that sustains them.

Supply Chain Engineering ensures repeatability, risk reduction and long term availability across multi-supplier networks.

It requires controlled integration, tooling validation, and documented transitions between suppliers.

For complex or non-standard supply chains

Certain projects require deeper strategic alignment before execution. In such cases, SHAMANA uses a Deep Dive Review to evaluate structure, risk exposure and execution feasibility before engagement.

Frequently Asked Questions

Q1: What is Supply Chain Engineering?

A1: Supply Chain Engineering is the discipline of designing, integrating, and stabilizing complex supply ecosystems to reduce vendor risk, ensure repeatable deliveries, and support long-term availability.

Q2: How does SHAMANA deliver Supply Chain Engineering?

A2: SHAMANA combines China sourcing integration, multi-supplier architecture, tooling validation, risk mitigation, and documented execution to support industrial and institutional deployments.

Q3: When should a company use Supply Chain Engineering?

A3: When repeatability, scalability, and continuity across suppliers are business priorities, especially for hardware, infrastructure, or multi-location deployments.