Project G308 – DOCUBOX | Fully Documented Hardware Integration Case Study

- Dec 26, 2025

- 4 min read

Iterative HardIterative Hardware Development, Integration & Deploymentware Development, Integration & Deployment

This DOCUBOX hardware integration case study documents the complete development, testing, and deployment process of Project G308.

What Is Documented in Project G308

Technical design |

|

System architecture & integration |

|

Iterative development |

|

Testing & validation |

|

Compliance & certifications |

|

Production & assembly |

|

Packaging & delivery |

|

Deployment readiness |

|

Why this matters

This level of documentation:

reduces implementation risk

supports procurement and audit processes

proves delivery capability beyond concepts or prototypes

Project G308 is not presented as a concept.It is presented as a documented, delivered hardware system.

Project Overview

Project Code: G308Product: DOCUBOX – Smart Document Drop BoxClient: Software provider for public authorities (Eastern Europe)Application: Secure submission and collection of official documents outside office hoursDeployment: Outdoor / semi-outdoor, unattended public use

Project G308 represents the development and deployment of a purpose-built DOCUBOX system, designed to act as a physical interface between citizens and public or private authorities, enabling document handover and retrieval beyond standard working hours.

The project supports the modernization of public administration, improving accessibility, efficiency, and user experience while maintaining security and traceability.

The Challenge

The client already owned and operated the software platform used by authorities to manage document workflows.

SHAMANA was not involved in software development.

The challenge was entirely focused on hardware design, integration, and delivery.

Initial inputs from the client included:

Maximum external dimensions

Required number of document compartments

Functional and usage requirements

Integration constraints with existing software

The DOCUBOX hardware needed to be:

Reliable in real public environments

Scalable across multiple deployments

Adapted to operational constraints, not theoretical ones

SHAMANA’s Role

SHAMANA acted as hardware integration and delivery partner, assuming full responsibility for the physical system.

Our scope covered:

Mechanical design coordination and enclosure definition

Sourcing and validation of all hardware components

Electronics and access-control integration

Display engineering optimized for outdoor use

Assembly supervision in factory

Packaging and delivery coordination

This was a system-level hardware project, not a one-off build.

Iterative Development Approach (Key to Project Success)

Project G308 was developed through multiple production iterations, each one refining the system based on real-world feedback and validation.

First Series

The initial production batch validated:

Overall architecture

Functional logic

Integration between mechanical, electronic, and display subsystems

This phase also revealed practical improvement points, typical for any real hardware deployed in the field.

Subsequent Series – Continuous Optimization

Based on observations and usage feedback, adjustments were implemented, including:

Improved cable routing and positioning

Adjusted sheet metal thickness for increased rigidity

Optimized hinge types for durability and long-term use

Refined internal layout for service access and reliability

Each iteration resulted in a more robust, mature product, aligned with operational realities.

This iterative process reflects engineering discipline, not compromise.

Key Hardware Highlights

Purpose-Built Display System

Exclusive use of BOE industrial-grade display panels

Custom backlight configuration, adjusted specifically for outdoor visibility

Brightness calibrated for high ambient light conditions

Mechanical adaptation ensuring long-term stability

The display serves as a guidance and interaction interface, not a general-purpose terminal.

Document-Centric Design

Secure compartment-based architecture

Designed specifically for official document handling

Clear separation between user interface and document storage

Optimized for unattended public use

Electronics & Access Logic

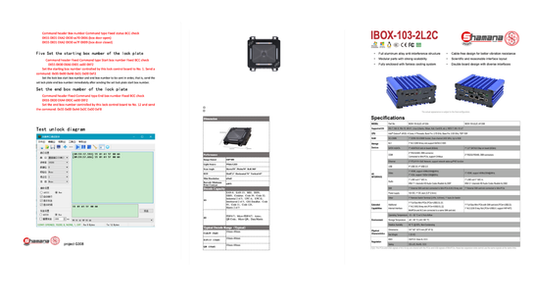

Industrial PC selected for continuous operation

Integrated control boards for compartment opening mechanisms

QR code integration enabling secure access and traceability

Proximity-based lighting system improving usability in low-light conditions

Assembly Supervision & Delivery

Final assembly was actively supervised in the factory to ensure:

Correct mechanical and electronic integration

Functional validation before packing

Consistent execution of design intent

SHAMANA coordinated:

Industrial packaging

Factory release

Delivery logistics

All DOCUBOX units left the factory fully assembled and ready for installation.

DOCUBOX Hardware Integration – Deployment & Results

Approximately 60–70 DOCUBOX units delivered across multiple production series

Deployed in real public-facing environments

Product stability increased with each iteration

No major unresolved issues reported

Hardware platform validated for continued rollout and scaling

Project G308 evolved from concept to a mature, field-tested hardware solution.

Why Project G308 Matters

Project G308 demonstrates SHAMANA’s ability to:

Deliver custom-adjusted hardware systems aligned with project constraints

Apply an iterative engineering approach based on real usage

Take ownership from development through factory supervision and delivery

Support digital transformation initiatives for public and private authorities

It highlights the difference between theoretical design and hardware that improves through deployment.

Next Step

Planning a document interface system for public or private authorities?

This project is fully documented, from concept to deployment.