Hexapolar Diagnostic Cable Assembly for Utility Applications (PR034)

- Dec 30, 2025

- 2 min read

Updated: Jan 7

Safety-Critical Industrial Cable for Utility Applications (ENEL Italy)

Hexapolar Diagnostic Cable Assembly Technical Overview

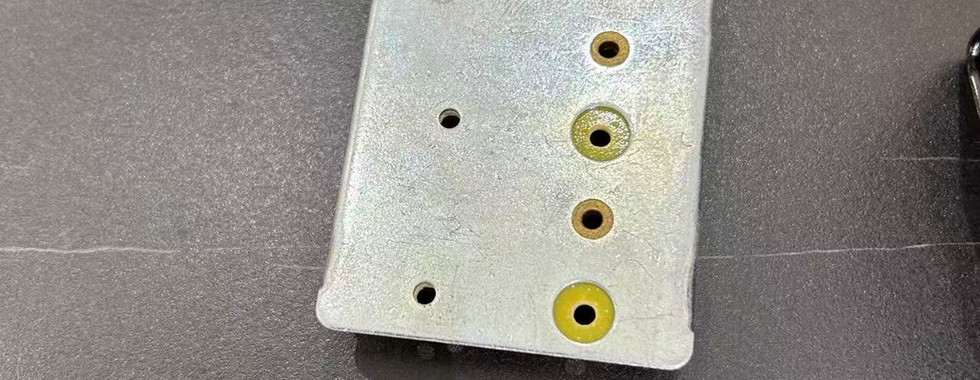

This project involved the development and industrialization of a custom hexapolar (6-pole) diagnostic cable assembly intended for utility-grade field use.The final application is within ENEL infrastructure, where electrical safety, mechanical robustness, and full traceability are mandatory.

This was not a standard cable supply. The customer required a fully controlled assembly, capable of withstanding repeated connection cycles, harsh industrial environments, and strict internal compliance audits.

This hexapolar diagnostic cable assembly was engineered as a safety-critical solution for utility-grade applications.

Customer Requirements (Utility-Grade)

The brief specified:

Custom 6-pole diagnostic connector

High insulation margins between conductors and connector body

Robust strain relief for repeated handling in the field

Mechanical integrity over long service life

100% electrical and insulation testing

Traceable conformity documentation per unit

In short: product + process + proof.

A. Custom Connector Development

Dedicated plastic components and tooling were developed to ensure:

precise geometry

stable insulation distances

scalable production

B. Supplier Engineering (Key Success Factor)

We selected and validated:

industrial-grade contact terminals (long-term stability)

certified multi-core cable suitable for utility diagnostics

an assembly partner capable of process discipline, not craft assembly

Supplier quality was treated as an engineering variable, not procurement.

C. Assembly Process Control

Defined parameters included:

stripping lengths

crimp profiles

torque values for enclosure screws

strain relief validation steps

This removed operator-dependent variability.

Testing & Compliance

Every single cable is delivered with a conformity test package, including:

Electrical continuity & pin mapping

Insulation resistance verification

Dielectric withstand testing

Mechanical integrity checks

Testing is performed on the final assembled unit, not just components.

What Was Delivered

The customer received:

Custom hexapolar diagnostic cable assembly

Utility-grade connector architecture

Validated tooling & industrialized process

Controlled and repeatable assembly flow

100% tested products with traceable documentation

Why This Case Study Matters

This hexapolar diagnostic cable assembly was developed as a safety-critical solution for utility-grade applications.

This project shows the difference between:

“supplying a cable” and engineering a safety-critical industrial solution

It demonstrates SHAMANA’s ability to:

design for compliance, not just function

control suppliers as part of the system

deliver products ready for utility-level audits