Project PR166 — Industrial 15.6” Display Module

- SHAMANA Technical Team

- Dec 27, 2025

- 2 min read

Updated: Dec 29, 2025

Engineering-led design, assembly optimization & production delivery

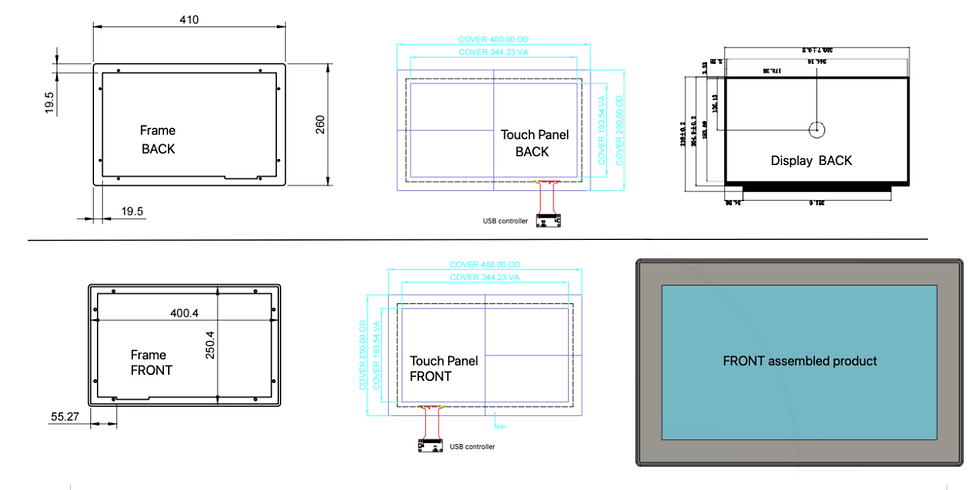

PR166 is a fully integrated 15.6 inch industrial display module engineered for direct installation into compact industrial PC systems. Unlike standard display sourcing, the client needed a production-ready assembly: bonded PCAP touch screen, a custom anodized aluminum frame, stable HDMI→LVDS controller integration, and repeatable mounting logic suitable for volume manufacturing. SHAMANA validated the mechanical design, optimized assembly by switching to integrated threaded studs, implemented functional and aesthetic QC, and delivered ~800–1,000 units to an Italian industrial manufacturer.

Project Snapshot

Industry: | Industrial electronics / Compact PC systems |

Display size: | 15.6” |

Interface: | Projected Capacitive (PCAP), bonded |

Touch: | Projected Capacitive (PCAP), bonded |

Frame: | Custom anodized aluminum |

Design: | Exclusive, client-specific |

Production volume: | ~800–1,000 units |

Destination: | Italy (industrial manufacturer) |

QC: | Functional & aesthetic inspection prior to delivery |

Specs Card

Display: 15.6”

Touch: PCAP bonded display

Frame: anodized aluminum

Controller: HDMI to LVDS display module

Volume: ~800–1,000 units

Destination: Italy

QC: functional + aesthetic

The Challenge

PR166 was not a standard display sourcing task.The client required a production-ready display module, not just a panel—one that could be directly integrated into compact industrial PC assemblies with:

mechanical rigidity

visual consistency

clean electronics integration

repeatable assembly flow

The challenge was to engineer a solution that scales, not improvise a prototype.

Engineering & Execution

SHAMANA handled the project end-to-end, starting from mechanical design validation to electronics integration and assembly logic.

Key engineering decisions included:

Custom anodized aluminum frame Chosen for rigidity, durability, and industrial aesthetics—avoiding deformation and tolerance drift common in plastic housings.

Bonded PCAP touch solution Eliminating layered assemblies improved optical clarity, durability, and reduced long-term failure risks.

Dedicated HDMI → LVDS controller integration Ensured signal stability and compatibility with compact PC architectures, avoiding generic or unstable off-the-shelf conversions.

Assembly Optimization — The Turning Point

During real assembly testing, an initial spacer-based mounting solution proved functional but inefficient for production.

SHAMANA re-engineered the mounting logic by introducing integrated threaded studs, which resulted in:

faster assembly time

fewer components

reduced risk of misalignment

improved repeatability in production

This change alone significantly improved manufacturability and consistency.

Quality Control & Validation

Before shipment, each unit underwent QC checks, including:

Functional testing (display, touch response, controller behavior)

Aesthetic inspection (frame finish, alignment, surface integrity)

Only units meeting both technical and visual standards were approved for delivery.

Packaging & Delivery

The final modules were packaged using protective, transport-safe solutions designed to:

prevent mechanical stress

protect electronics and bonded glass

ensure zero-damage delivery to the Italian production site

Final Outcome

PR166 was delivered as a fully integrated, production-ready display module, combining:

mechanical integrity

electronic stability

optimized assembly flow

consistent quality across a 4-digit production run

The project successfully transitioned from pilot to volume production without compromises.

Ready to validate your industrial module? Start a pilot run (engineering + QC included).

Why This Project Matters

PR166 reflects SHAMANA’s core strength:engineering-driven sourcing and execution, not catalog reselling.

We operate as a technical production partner, capable of redesigning, optimizing, validating, and delivering complex industrial components at scale.